Selection of carbon fabric weave

Carbon Fiber Weaves Explained: Twill, Plain, and UD When selecting a carbon fiber fabric, the weave pattern plays a key role in determining how the material looks, performs, and behaves during production. Each type of weave has its own advantages and best-use scenarios. The three most common types are Plain, Twill, and UD (Unidirectional).

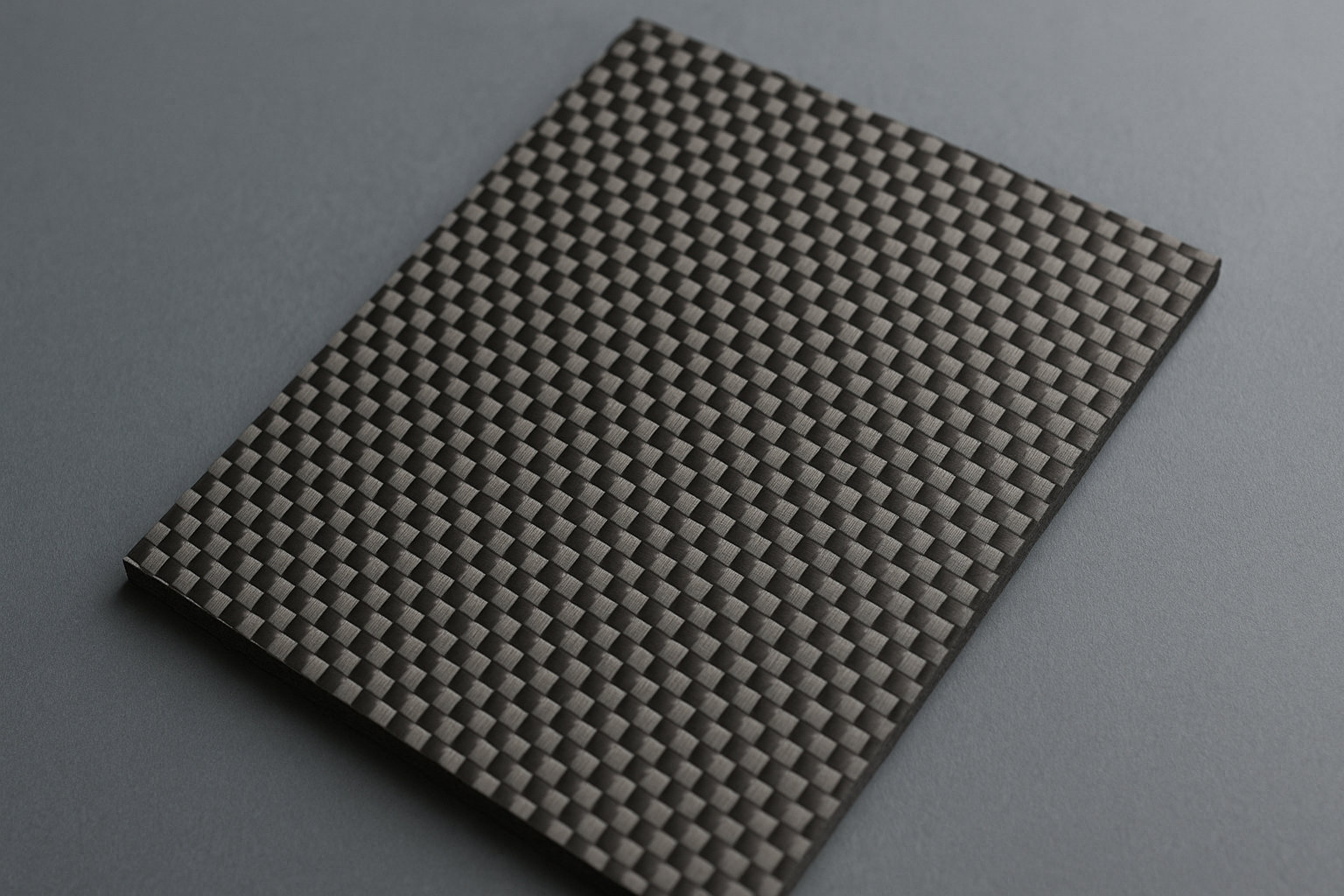

Plain Weave

The Plain weave is the simplest and most traditional type of carbon fiber fabric. In this structure, each fiber alternates over and under the next, forming a balanced, uniform checkerboard pattern. This construction gives the material consistent strength in both directions and excellent dimensional stability. Plain weave is known for its rigidity and resistance to deformation. However, it is less flexible and more difficult to apply to curved surfaces compared to other weaves. It is also the most affordable type of carbon fabric, which makes it ideal for applications where performance and stability are more important than aesthetic appearance. Plain weave is commonly used for flat or simple-shaped components, reinforcing panels, or parts that require high reliability at a lower cost. It is a practical and durable solution for many structural applications.

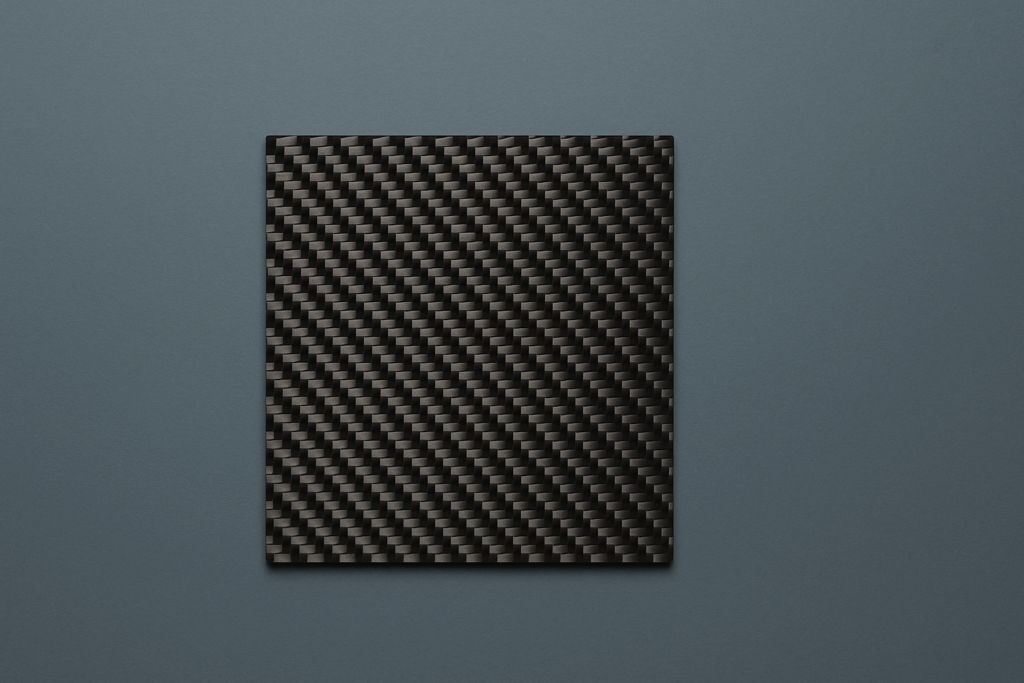

Twill Weave

The Twill weave is characterized by its distinctive diagonal or “herringbone” pattern. Each yarn passes over two and under two fibers, creating a smoother surface and a more flexible structure. This weave is popular not only for its mechanical properties but also for its elegant appearance. Twill fabric drapes better than Plain weave, making it easier to apply to complex shapes such as curved surfaces or aerodynamic structures. Although it is slightly less balanced in strength between directions, it still offers high performance and excellent durability. Twill weave is widely used in automotive parts, drones, bicycles, and sporting goods — wherever both strength and visual appeal are desired. It offers the best balance between functionality and aesthetics.

UD (Unidirectional) Fabric

UD, or Unidirectional fabric, differs from woven fabrics because all fibers are aligned in a single direction. There is no interlacing between warp and weft; instead, the fibers are held together by a light binder. This allows the fabric to achieve maximum strength and stiffness along one axis. Unidirectional carbon fabric provides outstanding performance where forces are predictable and aligned with the fiber direction. However, its strength across the fibers is much lower, so it is typically used in layered constructions, where multiple sheets are oriented at different angles (for example, 0°, 90°, and ±45°). UD carbon fiber is mainly used in high-performance applications such as aircraft components, drone frames, racing parts, and other engineered structures that require maximum load resistance in a specific direction. It is also more expensive than woven fabrics due to its specialized production and performance characteristics.

Choosing the Right Weave Each type of carbon fabric serves a different purpose: Plain weave is the most cost-effective and reliable choice for flat or simple structures that require uniform strength. Twill weave is ideal for complex shapes and visible components where both flexibility and an attractive surface finish are important. UD fabric is designed for advanced, high-performance engineering applications where maximum strength in one direction is required. Understanding these differences helps you choose the right material for your project — whether you’re building lightweight panels, precision components, or visually refined carbon fiber parts.