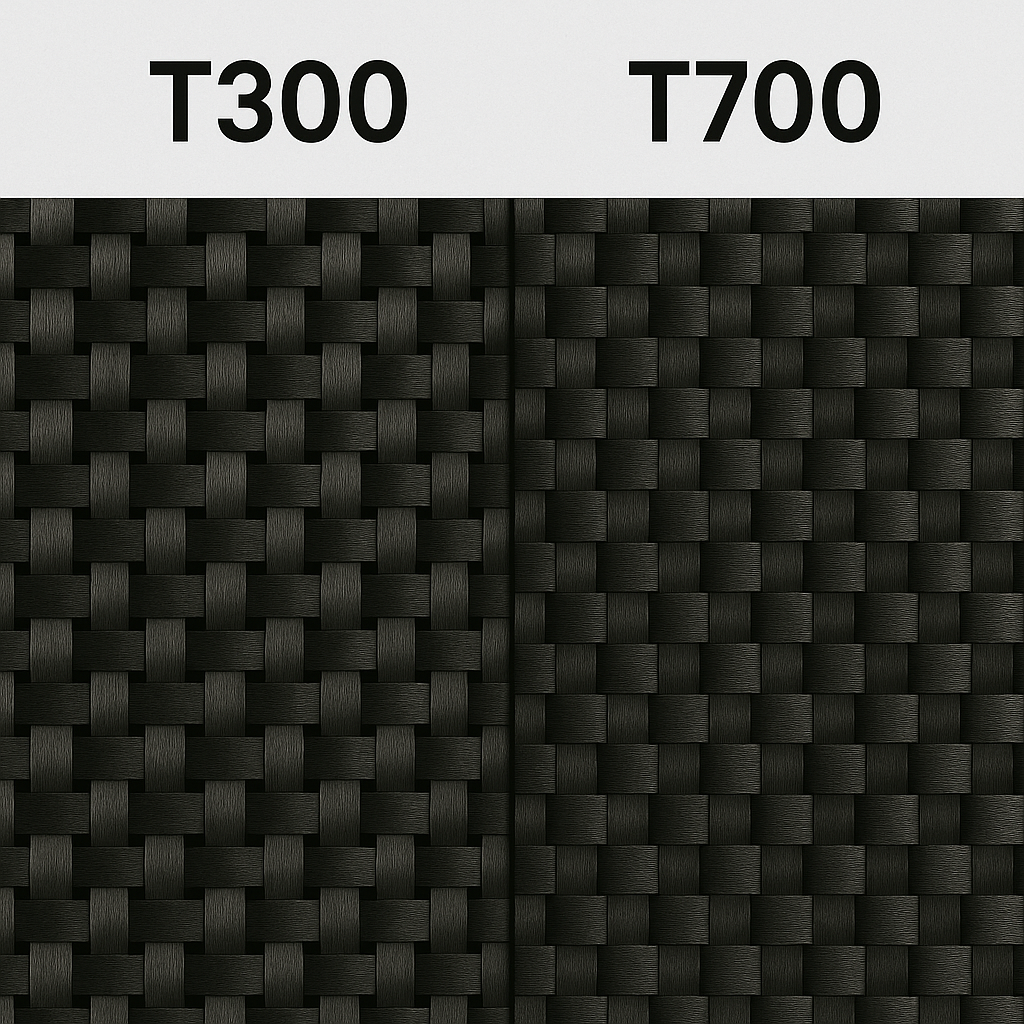

Carbon Fiber Fabric T300 vs T700:

Understanding the Difference and Their Functions

Carbon fiber is one of the most widely used materials in modern manufacturing. Its exceptional strength-to-weight ratio, high stiffness, and resistance to deformation have made it the ideal material for various industries such as aerospace, automotive, and sports. When it comes to carbon fiber, two terms you will frequently encounter are T300 and T700. This article will explore the difference between these two types of carbon fiber yarn and their specific functions.

Key Differences in Properties

T300 and T700 are two grades of carbon fiber that differ primarily in tensile strength, elastic modulus, and cost.

• T300 Carbon Fiber Yarn:

◦ Tensile Strength: ~3000 MPa (Megapascals)

◦ Elastic Modulus: ~230 GPa (Gigapascals)

◦ Status: A standard, well-established, and cost-effective grade.

• T700 Carbon Fiber Yarn:

◦ Tensile Strength: ~4800 MPa (Megapascals)

◦ Elastic Modulus: ~300 GPa (Gigapascals)

◦ Status: A higher-performance fiber with superior mechanical properties.

The Bottom Line: T700 yarn is approximately 60% stronger and about 30% stiffer than T300. As a result, T700 is stiffer, stronger, and more expensive.

Functions and Applications

Both types of carbon fiber are commonly used in various applications, but their specific use depends on their properties and the project requirements.

T300 Carbon Fiber: The Balance of Reliability and Affordability

T300 is often used where a balance of strength, reliability, and cost is required. It is an excellent material for automotive parts, sports equipment, and industrial goods where cost is an important factor.

• Common Applications:

◦ Automotive: Parts where weight reduction and strength are beneficial, but ultimate performance isn’t the sole driver.

◦ Sports Goods: Rackets, fishing rods, and other equipment where high-end specs are not critical.

◦ Industrial Products: Casings, panels, and structural components.

◦ Aerospace & Defense: Used in secondary structures and components where a higher strength-to-weight ratio is important.

T700 Carbon Fiber: Maximum Performance and Stiffness

T700 is typically used where maximum strength and stiffness are required. It is the go-to material for high-performance applications where minimizing weight while maximizing performance is crucial.

• Common Applications:

◦ High-End Sports Equipment: Professional-grade tennis rackets, golf club shafts, and competition bicycle frames, where stiffness directly impacts performance.

◦ Aerospace: Primary structural components of aircraft and satellites, where every kilogram saved is critical.

◦ Wind Energy: Manufacturing of wind turbine blades that must withstand enormous mechanical stresses.

◦ Advanced Automotive: Components for supercars and race cars where top-tier strength and low weight are non-negotiable.

In conclusion, T300 and T700 are two grades of carbon fiber that differ in their properties and applications. While T300 is a more cost-effective alternative offering a proven balance of strength and affordability, T700 is a premium option providing maximum tensile strength and stiffness. Both types of carbon fiber have their specific uses, and the choice between them ultimately depends on the technical requirements and budget of the application.

Contact us now to find the right material for your project!